We are professionals in the field of metal sheet processing. We can handle your order based on demanding requirements within the deadline and quality agreed using modern production technologies. We will be pleased to participate in development and improvement of your existing products.

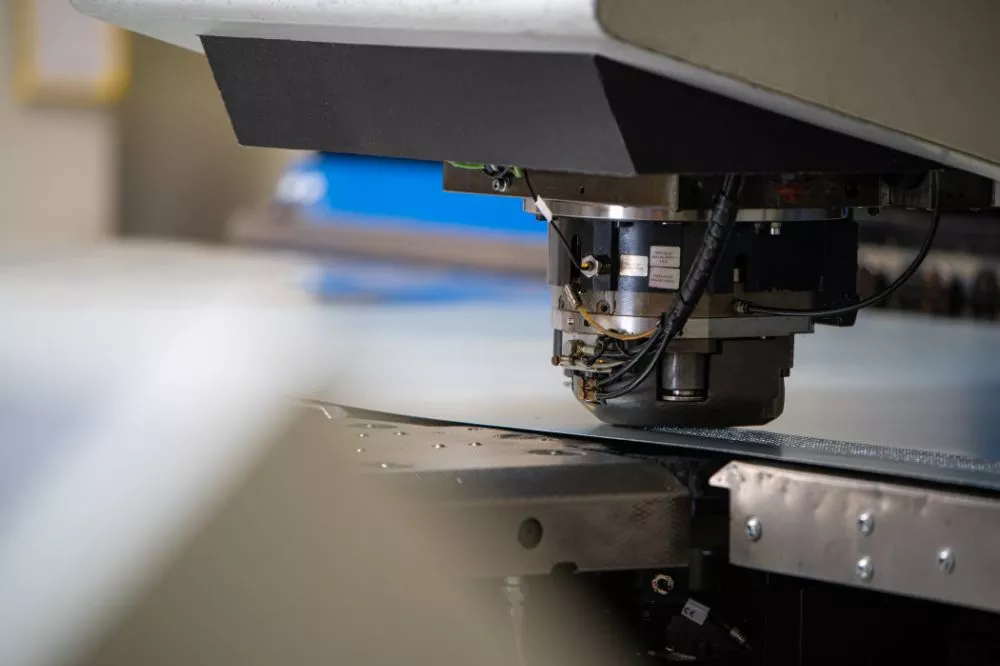

Description of the technology:

We use CNC-based TruPunch 3000 cutting presses to cut metal sheets that permits us to cut metal sheets of various qualities up to 3mm

and size 3,000×1,250mm. Among other, the presses are fitted with different tools for shaping of the metal sheets: (Multibend, broaching, countersink, grooves, ribs, bowls, elongation, thread cutting, and more.) We use multiple punches for production of perforated metal sheets to speed up production and for effective component prices.

Press parameters:

Type: TruPunch 3000

Pressing force: 180 kN

Maximum material format: 3,000 × 1,250 mm Maximum thickness of cut material: 3mm for black, zinc-coated, aluminium, and stainless-steel sheet

Description of the technology:

We bend the required product according to the drawing documentation using TruBend 5130, 5170, 5050 CNC bending presses from the cut-outs or die cut shapes supplied by you. In addition to the normal sheet metal bending, the presses also have a function of moving the lower tool called folding without die replacement.

Press parameters:

Type: TruBend 5130, 5170, 5050

Pressing force: 130 kN, 170 kN, 50 kN

Maximum extrusion bending length: 3,230mm Maximum force of bent material: 3mm for black, zinc-coated, aluminium, and stainless-steel sheet

Description of the technology:

Our new TRUMPF Fiber L3030 laser with automatic sheet metal loading can be used for the production of thick sheet metal parts or parts with complex shapes.

The machine can process various types of materials in the format of 3,000×1,500mm, thicknesses: for structural steel up to 20mm, for stainless-steel up to 12mm and for aluminium and its alloys up to 8mm and copper.

Press parameters:

Type: Fiber L3030

Power: 3200W

Maximum material format: 3,000×1,500mm

Maximum material wall thickness: black 20mm, stainless-steel 12mm, aluminium 8mm, copper Maximum production deviation: +/- 0.1 mm

Parts can be further cooperated (welding or painting) or complex assembly of the final product can be ordered, including documentation and prescribed components. Our dedicated design team will also deal with all your atypical requirements or modifications of your standard and atypical products.

STAVOKLIMA s.r.o.

BUDĚJOVICKÁ 450, 370 01 HOMOLE